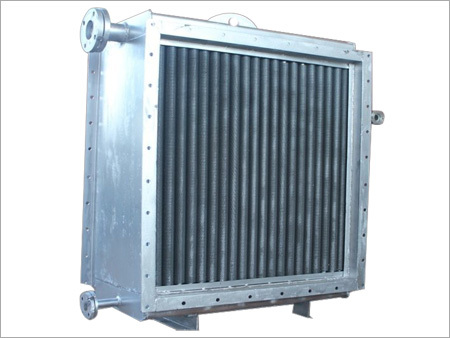

Finned Tube Radiator

Finned Tube Radiator Specification

- Material

- Carbon Steel / Stainless Steel

- Water Content

- Adjustable as per design

- Central Distance

- Customizable (commonly 300-1500 mm)

- Working Pressure

- Up to 16 Bar

- Rough Weight

- 30-90 kg (varies with size/model)

- Thermal Pressure

- Up to 120C

- Dimension (L*W*H)

- Can be customized, typical length 1-6 m

- Advantage

- High heat transfer efficiency, compact construction, suitable for high temperature and high pressure operations

- Corrosion Resistance

- High, due to protective coatings

- Fin Spacing

- 2.5 mm 12 mm (as per requirement)

- Heat Output

- 400-2500 W/meter (as per design and application)

- Fin Material

- Aluminum or Carbon Steel

- Surface Treatment

- Epoxy/Powder coating or galvanized

- Installation Type

- Horizontal / Vertical wall mounting

- Color

- Grey/Black, other RAL colors available on request

- Test Pressure

- Up to 20 Bar

- Insulation

- Optional, as per customer requirement

- Application

- Industrial heating, greenhouses, textile, chemical and food industries

- Tube Diameter

- 19 mm, 25 mm, or as specified

About Finned Tube Radiator

Our company is one of the famous company in the business for offering Finned Tube Radiator. Provided tubes are available in various sizes and shapes as per the requirements. It is perfectly designed and appreciated for leak proof, durability, & easy installation features. Based on latest technology, our radiator finds usage in various industry applications. Finned Tube Radiator can be customized as per the specification of customers.

Versatile Applications Across Industries

Finned tube radiators are ideal for environments requiring efficient heating, such as greenhouses, textile mills, food processing units, and chemical plants. Their robust design and customizable features ensure reliable operation in demanding settings where precise temperature control and durability are essential.

High-Performance and Durable Construction

With materials like carbon steel and stainless steel, along with protective surface treatments, these radiators offer high corrosion resistance and withstand high pressures and temperatures. The compact build enables efficient heat transfer while occupying minimal space, making them suitable for both wall-mounted horizontal and vertical installations.

FAQs of Finned Tube Radiator:

Q: How do I choose the right fin material and spacing for my finned tube radiator application?

A: The fin materialeither aluminum or carbon steelshould be selected based on the required thermal conductivity and environmental factors like humidity. Aluminum maximizes heat transfer efficiency, while carbon steel offers superior mechanical strength. Fin spacing, ranging between 2.5 mm to 12 mm, can be adjusted to balance airflow and heat exchange as per your specific industrial requirements.Q: What is the typical installation process for these radiators?

A: Installation involves wall mounting, either horizontally or vertically, depending on space and heating distribution needs. The radiators are securely fixed to a supporting surface, connected to the plumbing system, and checked for leaks at the specified test pressure (up to 20 Bar). Professional installation is recommended to ensure optimal performance and safety.Q: When should I opt for optional insulation with my finned tube radiator?

A: Optional insulation is recommended when there is a need to minimize heat loss or enhance safety by preventing exposed hot surfaces. This is particularly useful in applications needing higher energy efficiency or installations in areas with direct human contact.Q: Where are these finned tube radiators most effectively used?

A: They are best suited for industrial environments, such as textile mills, chemical processing plants, greenhouses, and food industry facilities. Their high heat transfer efficiency and customizable configurations make them ideal for demanding heating applications in these sectors.Q: What are the benefits of choosing a finned tube radiator with protective coatings?

A: Protective coatings like epoxy, powder coating, or galvanization significantly enhance corrosion resistance, increasing the radiators lifespan and reliability, especially in harsh or humid environments. This also lowers maintenance requirements and preserves heat transfer efficiency over time.Q: How does the radiators design accommodate different pressure and temperature requirements?

A: These radiators are constructed to handle working pressures up to 16 Bar and thermal pressures up to 120C, making them suitable for high pressure and high temperature industrial processes. Parameters like wall thickness, material selection, and surface treatment are tailored to your operational demands.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry